Built to Serve Our Customers

Rebuilds

Your system may need a tune up, whether planned or not. Fortunately, Ludman machines and systems are built for the long haul. We aim to reduce total cost of ownership of your plant by building rugged reliable equipment. In the event that your Allis-Chalmers, Ludman or similar equipment of different brands is in need of refurbishing services, contact us for a preliminary consultation, plant audit and inspection.

OEM Parts

We offer certified OEM replacement parts. Third parties cannot match the quality we provide. We abide by the irreplaceable specifications proprietary to OEM quality, such as material, hardness and methodology–all backed by an OEM warranty. Ludman supports every part on its machines from full roll and bearing assemblies to hardware. Legacy parts components match the original Allis-Chalmers specifications and design. Contact us for more information.

Assembly

We take pride in offering quality products made in the USA. All assembly of Ludman products occurs with great attention to detail and focus on quality, right here in Milwaukee, WI, USA.

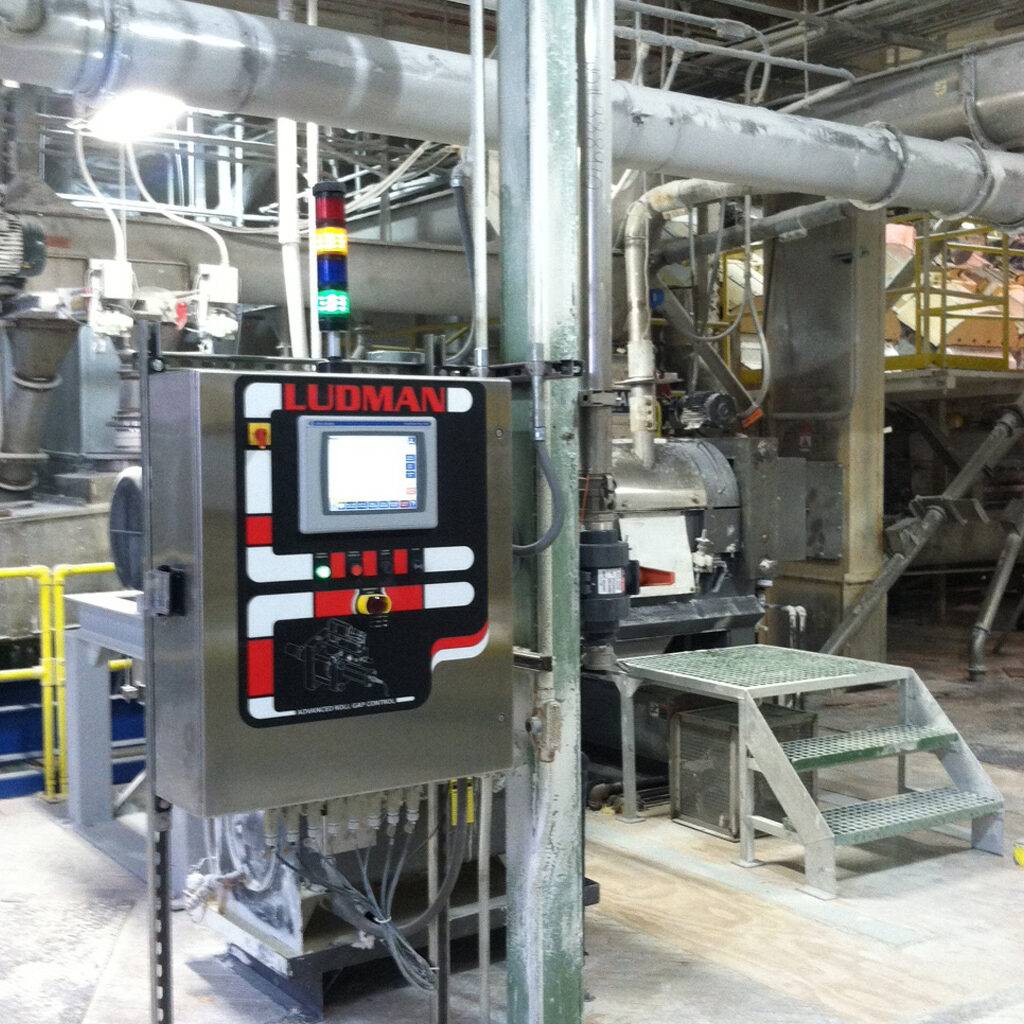

Field Service

Ludman possesses the intimate knowledge of your machine and its components. Infromation such as material, hardness, and best methodology, comes from our design “know-how” and vast experience. We are in the best position to make qualified repairs.

Plant Audit

Ludman inspects, repairs and rebuilds machines of any make and model, including non-Ludman machines. A plant audit and multi-point inspection may lead to improvement of the overall performance of your system. Reduce your total cost of ownership.

Inspection Services

We offer the latest state of the art inspection process through our CMM inspection system. A comprehensive report will convey to you the quick and accurate results. Stay informed with the information you need to operate most efficiently.

Coordinate Measuring Machine (CMM)

Engineering & Development

A large part of service is evaluating new or existing designs that may need tweaking, as it affects your bottom line. We are committed to innovating, as well as relying on our time-tested designs. We help our customers from beginning to end with basic and detailed engineering services and process development.

Training

Understanding how our machines work are critical to the success of your operation. We have seen companies that excel or fail in this area. We believe training and customer education is imperative to getting the most out of your Ludman machine.

Pilot Test Laboratory

Understand the needs of your material application prior to building your machine.