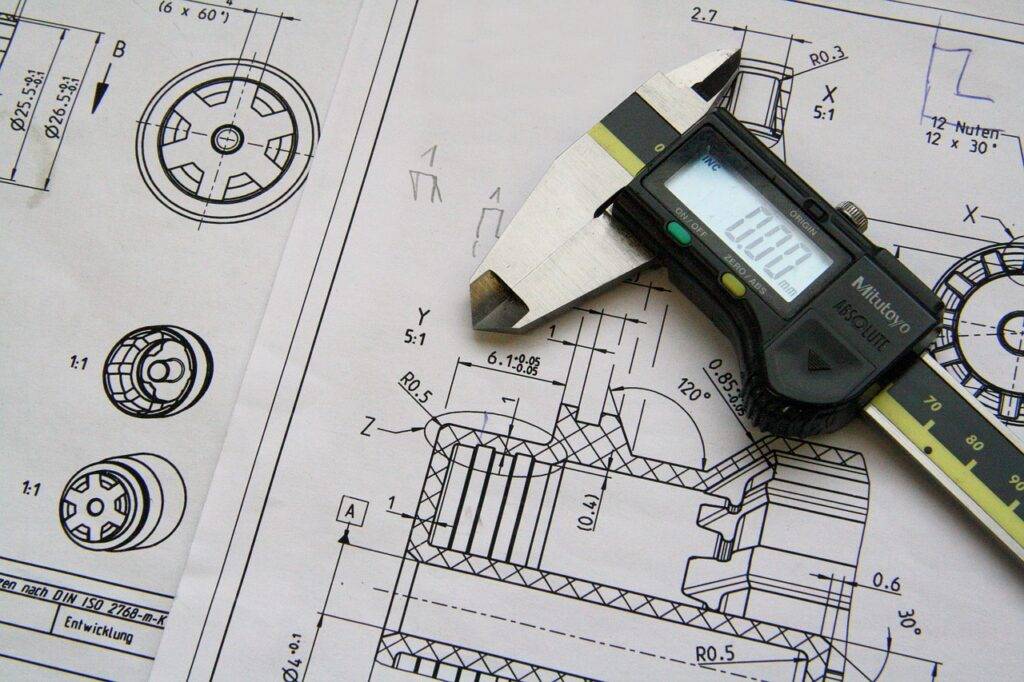

Engineering

Basic and detailed engineering services

Ludman Industries provides both basic and detailed engineering services for your entire process system, individual machines or components. Our goal is to maximize efficiency of your plant, beginning with our process expertise. Ludman brings ideas from concept to conclusion to give you the results you need. We take an immense amount of ownership over project details to account for even the slightest variables impacting your project.

Innovative designs

We continually look for ways to improve our products and solve problems that arise in harsh, corrosive environments. Typically, temperature, moisture, corrosive materials, and so on can cause a number of problems that we have managed to solve. We build your machine to fit the environment you are in, while providing the greatest possible outcome.

Custom solutions

The environment your machines are in dictates the design of your machines. We can solve a variety of problems by accounting for the whole picture prior to build. A great deal of basic and detailed engineering services include understanding your needs and the environment, as well as accounting for the many factors that influence production.

Basic Engineering

You can often expect the following to take place in the basic engineering stage:

• Undergo conceptual process studies, including material balances, process flowsheets showing key equipment and material balance, etc.

• Design preliminary plant layout plan, equipment selection, sizing and process specifications, connections, supports and access

• Establish preliminary piping and instrumentation diagrams (P&IDs), engineering calculations and analysis pertinent to the design

• Provide preliminary equipment list with estimated horsepower

• Define control and safety devices

• Perform studies to supply a basic design package to provide data for detailed

• Build a process package

Front End Engineering Design

You can anticipate the following to take place in front end engineering design:

• Finalize process flow diagrams (PFD)

• Create material balance (HMB)

• Create mechanical data sheets of the main equipment, starting from the process specifications issued during the basic design and incorporating the specific requirements of codes and standards to be applied to the project

• Design preliminary civil, piping, electrical and instrumentation, motor lists and diagrams, MCC and control room locations

• Create general arrangement (GA) and 3D model

• Develop process and utility P&IDs released for detailed

Detailed Engineering

The following often takes place in detailed engineering:

• Complete design plans for equipment layouts and finalize GAs

• Establish thermal rating of heat exchangers

• Release P&IDs to construction

• Finalize equipment list, installation and material specifications

• Develop detailed piping drawings, including isometrics and stress calculations

• Develop detailed drawings, related to instrumentation, electrical facilities and civil works

• Manage vendor drawings

• Control cost and schedule

• Start up procedures

• Finish studies to be performed before construction of the plant