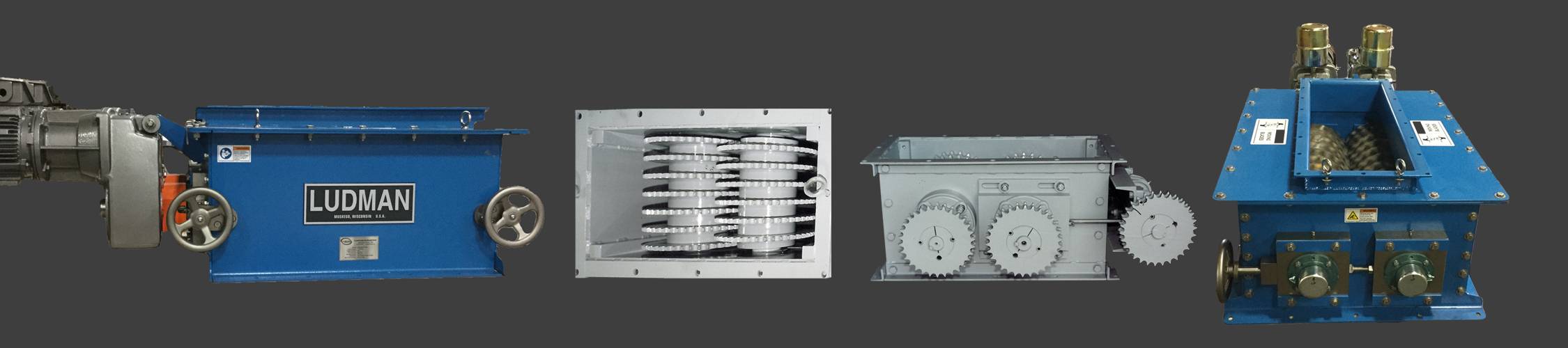

Ludman Flake Breakers

Heavy duty, rugged design built to process high yields

Ludman Industries builds rugged flake breakers to process high yields generated by our roll compactor and high precision grinding mills.

Ludman Flake Lump Breakers utilize two counter rotating toothed rotors driven by chain and sprockets, powered by two HD-rated drives. Likewise, these reliable rotors sheer and crush compacted sheets of product into a manageable size for precision grinding by roll granulating press.

Moreover, through innovative design and unmatched quality workmanship, the Ludman Industries Flake Lump Breaker machine's rugged design is capable of accepting many different types of materials. To illustrate, it breaks them into a material size acceptable for further controlled particle size reduction, or to create smaller sized material for another process.

In other words, the flake lump breaker, consisting of two counter-rotating, toothed rotors, reduces the sheet-like material by impact. Therefore, each rotor in the pair supplies the required spacing to provide the product particle size range desired. However, one rotor in the pair is manually adjustable to increase or decrease the gap between them to accommodate changes in the thickness of the material being fed to the breaker.

Additionally, the rotors work in tandem by support of heavy duty double row spherical cartridge bearings, sealed from the machine’s interior by an additional seal to protect each bearing from dust contamination and thus providing long and trouble free bearing operation. In conclusion, due to high pressure and vibration during operation, the flake lump breaker typically mounts on a robust and solid structure.

Lastly, learn more about Ludman Flaking and Shredding Mills below.